A Bit Of Background

In the 1950s, the Elk River Coal & Lumber Company (ERC&L) had a modest logging activity in central West Virginia. Logs were hauled from the woods to the company’s sawmill at Swandale, behind 3-truck Shay #19. Theodore Burdette was the engineer of this locomotive, one of the last Shays in regular logging service. But a second locomotive, Climax #3 (c/n 1692), with engineer Raymond Davis at the controls, had important work to do, also. ( I described how I built a model of Climax #3 in the May/June 2015 GAZETTE.) Davis’ train, referred to as the “steel train,” consisted of two or three of the line’s older truss-rod flat cars loaded with ties, spikes and rail. This train and its crew were charged with extending the line further into the woods and picking up track when an area was logged out.

There was a modest engine house in Swandale where the Shay was serviced each day after returning from the woods, and Theodore and the other crew spent the night at the modest homes provided for them by the company. But Davis and Climax #3 stayed out in the woods, returning to Swandale only if the 1928-built locomotive needed major service. Davis’ accommodations out in the woods were less elegant than Burdette’s, and he and those who stayed in Swandale lived in his caboose.

That caboose, the subject of this article, generally remained near a small group of modest buildings deep in the woods at a spot known as Starcher. The name came from the company that the ERC&L Company had hired to fell the timber and get it close enough to the tracks so it could be loaded onto the log trains by ERC&L crews with their ancient American log loader.

Thanks To Cody Burdette

It has been my pleasure to have corresponded over many years with Cody Burdette, the son of Shay engineer, Theodore Burdette. As a teenager, Cody worked as a hostler at Swandale tending the fires in the logging locomotives overnight. He has crystal clear recollections of how it was back in the West Virginia woods in the 1950s, and has graciously passed along the information and accounts above, plus other information in this article, and for that I am grateful. These are stories that otherwise would have remained untold.

Cody reports that when staying at Starcher, Raymond would park #3 on a track adjacent to his caboose home and place a thick plank between the caboose’s platform and the cab of the locomotive. That way, when he needed to get back and forth to tend the locomotive in the night, he could simply walk the plank with no need to climb down from the caboose, and then back up into the locomotive. Cody also recalls that on the rare occasions that Raymond and #3, along with his caboose, were in Swandale, the engineer would sometimes stop by early in the morning and get hot water from the boiler of #19 for his hot morning coffee.

Finally, Cody’s recollection is that in the years he was with the ERC&L he never saw Raymond’s caboose with a coat of paint. I’ve found very few images of this caboose in service on the ERC&L. This is no doubt the result of the car spending its life out in the woods where there was no road access, and only a few rail fans got permission to ride the log trains out to where the caboose was parked. The few photos available confirm Cody’s recollection because they all show it badly weathered.

The Prototype

According to Alan Clarke’s book Coal Coke Railway, the Coal & Coke Railroad was located in central West Virginia and lasted from 1905 to 1916. It had twelve 4-wheel cabooses that were built between 1909 and 1913. By January 1922, the B&O had taken over the C&C and renumbered the cabooses C1700-C1711. The B&O designated them, logically enough, as Class C&C. The cabooses lasted until 1934 when the first one was scrapped, with the last being scrapped in 1954, although Clarke says one was sent to the ERC&L and served on that line until its demise. That this is an ex-C&C caboose is further reinforced by the broad curves in the side grab irons. It would have had a 13-foot, 3-inch wheelbase, and a length of 21-feet, 2-inches.

This car was similar to the B&O Class K-1 caboose. There was also a K-1 caboose on the ERC&L roster that was used on the log trains. That car has been restored and is in service at the Cass Scenic Railway in West Virginia. As a side note, the ERC&L’s American log loader is also at Cass. It sits on a flat car and appears in the consist in many of the photo sessions.

The Model

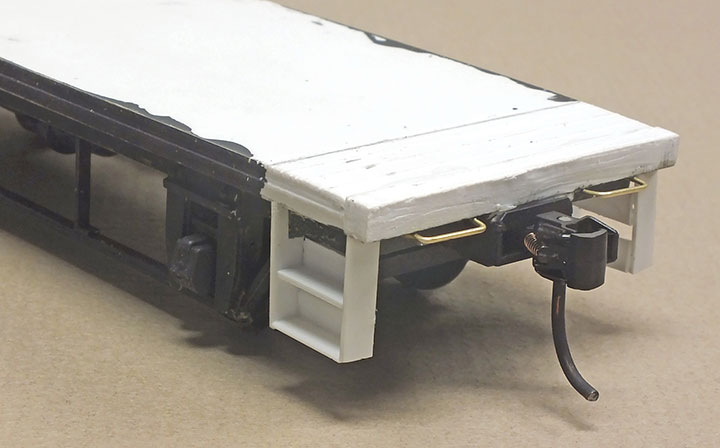

I chose to scratchbuild my model from styrene. As is my practice, I was more concerned about capturing the look and feel of the prototype rather than having every dimension exactly correct. My model measures 23-feet 4-inches over the end beams, and the wheelbase is 13-feet. Besides the overall proportions, the distinguishing features that I incorporated in my model include the diagonal reinforcing rods on the ends of the body, most of the grab irons, window awnings, roof walk, and the distinctive underbody structure between the axle journals.

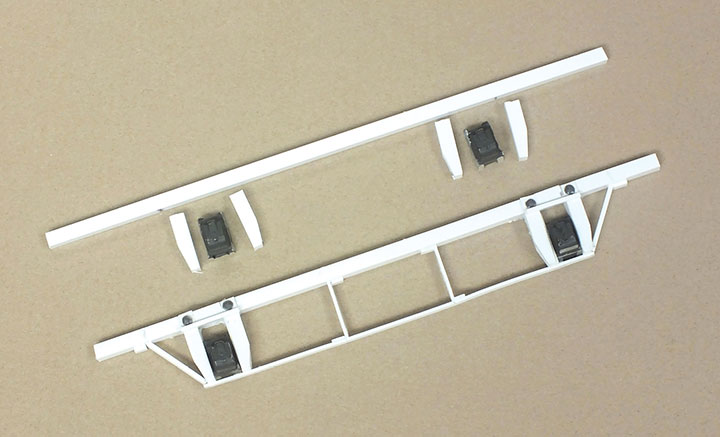

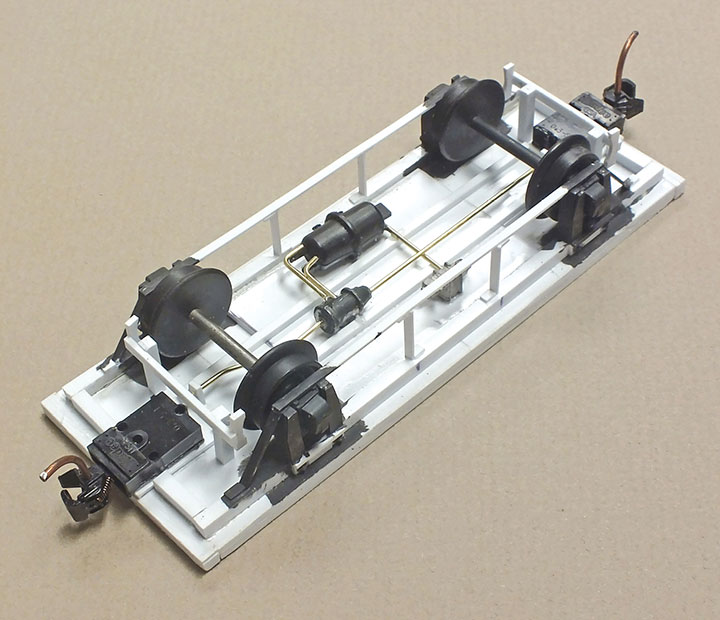

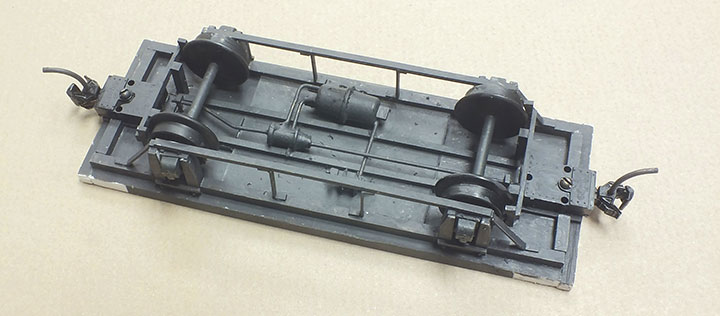

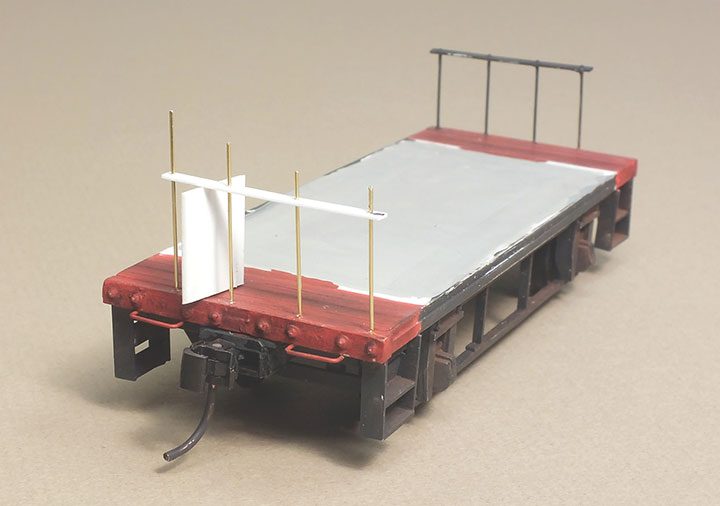

The floor is 1/8-inch-thick styrene and the end beams are 1/8 -inch-square pieces of styrene roughed up with a razor saw with appropriate NBW castings. The undercarriage details were built from styrene stock of various sizes, with the exception of the journals. These were cut from scrap box arch bar truck side frames with their sides ground flat and parallel. ACC was used to secure the metal journals to the surrounding styrene yoke structure. The corner steps were made from 1/8-inch, L-shaped styrene placed between side members made from .020-inch x .125-inch styrene. Brake rigging detail was freelanced under the floor including an air tank, valve and cylinder, plus some piping. Brake shoes were modeled with bits of styrene. Kadee #802 couplers were installed. The undercarriage was painted grimy black.

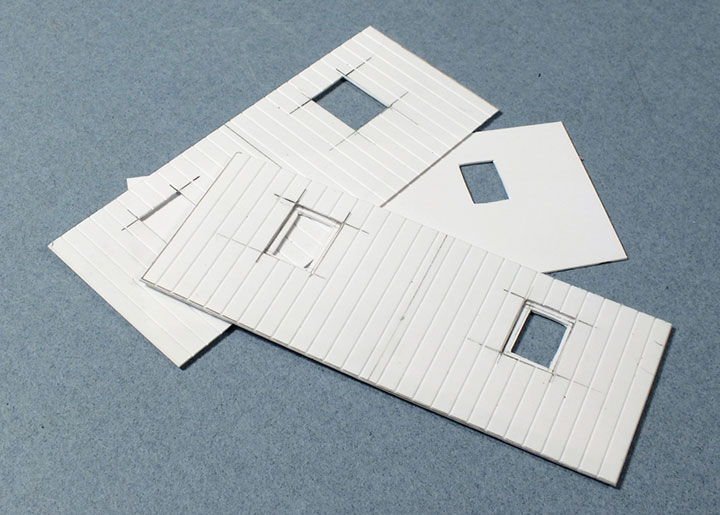

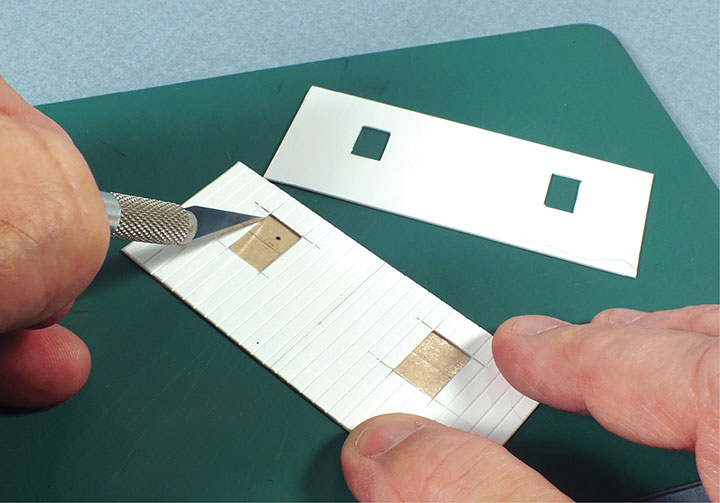

The four walls of the body were made by laminating two sheets of styrene. Evergreen V-groove .020-inch styrene was selected for the outer layer to represent individual boards. The exterior surface was scribed with the blade of a razor saw to add some wood-grain texture. The inner layer is smooth .020-inch styrene, and it forms the interior window frames. The end walls were made in a similar way. The two layers for each of the four walls were bonded together using 3M-brand adhesive transfer tape. This product has many uses for modelers and can be used to make almost any flat part “peel and stick.” Using this tape makes laminating styrene layers clean and easy, but they need to be carefully aligned as the tape prevents any adjustment once bonded.

The roof is .040-inch styrene, and the ribs on the roof are .030- x .030-inch styrene. The roof walk is .040-inch V-groove styrene. The end ladders are brass items from my scrap box. The grabs and end railing uprights were formed from .020-inch brass wire. The interior is not detailed but was painted light grey. Window shades are manilla card stock.

While the prototype was never well painted on the ERC&L, my style is to give models a well used, but not abused look. The body was painted caboose red and weathering was done by dry brushing streaks of light grey paint to represent peeled paint with grey and black pastel chalks for additional discoloration. The caboose carried no lettering of any kind.

Conclusion

I am happy with the way this model of an interesting little car turned out. For those not familiar with S scale, the model is about 4½-inches long. It looks great behind the log trains or on the steel train, and I’m sure Raymond would be tickled to know that his home-away-from-home is preserved on my S scale layout. It’s amazing that a car as small as this one survived in use as long as it did in the rough and tumble world of logging. While my rendition is in better condition than the prototype was during the period I model, that’s the fun of model railroading. You can make the world a little better place!