While McGiffert loaders were highly popular in the pine regions of the United States, their use in the heavy Douglas Fir coastal forests was very limited. The only use of the McGiffert in the Douglas Fir region was the Stimson Timber Company of Belfair, Washington, and the S. E. Slade Lumber Co. of Aberdeen, which was never documented.

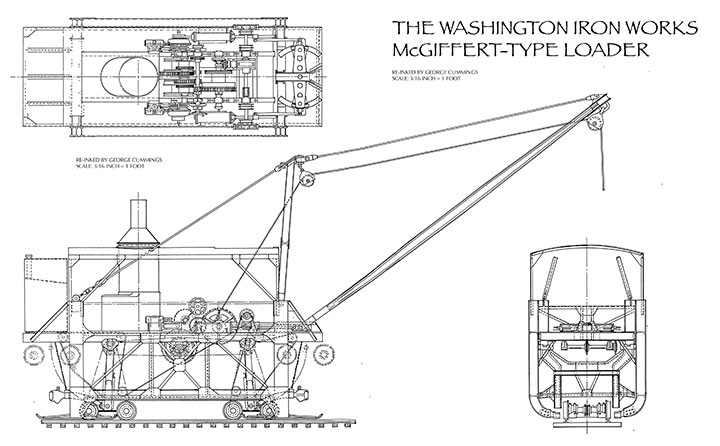

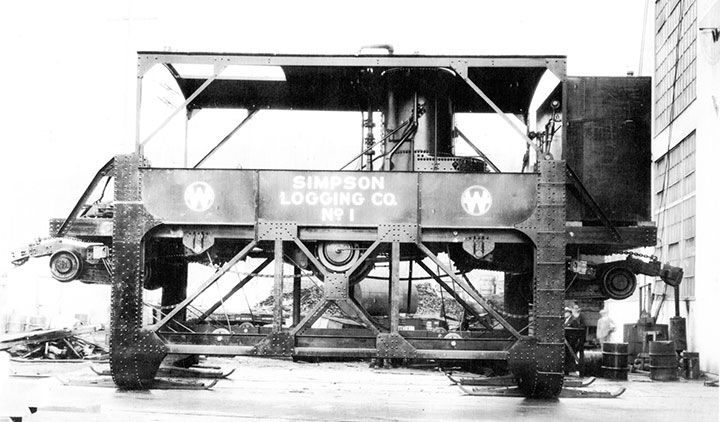

In the late 1920s or early 1930s, the patents of the McGiffert loader expired, and a few equipment manufacturers exploited the opportunity by building their own McGiffert-type loaders. One of the first was designed and built by Washington Iron Works of Seattle, Washington, for the Simpson Logging Company of Shelton, Washington. The text below is from The Timberman Magazine (date unknown, but the machine was built in 1930 and served the company well until the end of rail logging c.1949):

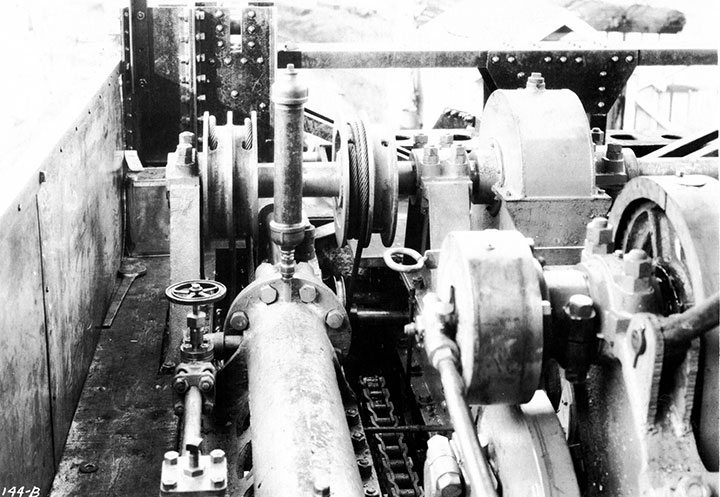

“Simpson Logging Company, Shelton, Washington recently put into operation a new tunnel type self-propelled boom loader. While machines of this same general type have been used in the pine regions for years, the Washington Iron Works has worked out several new features of operation to adapt this principle of loading to the heavier working conditions encountered in the fir sections. This new loader is an independent, steam-driven unit that does not require the assistance of a locomotive. In operating position, the trucks are raised to the underside of the main frame, forming a tunnel through which the empty logging cars have free and unobstructed passage on the main track to reach a position for loading under the steel boom. These features in conjunction with the fact that every operation incident to moving from one loading place to another is performed by the operator at his post, makes this new machine exceedingly efficient.

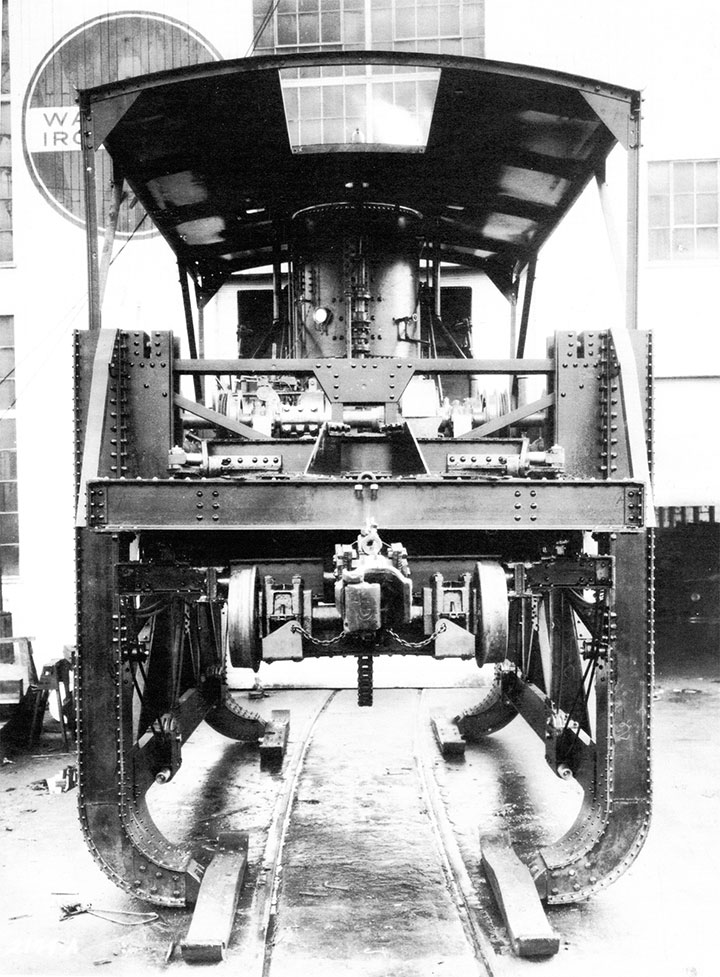

The main platform which carries all mechanisms is raised approximately 10 feet above the track and is supported at each side by heavy girder type legs having their extremities flexible shoes which adjust themselves to any irregularity in height of the ties upon which they rest. These shoes have sufficient length to distribute the load over a large number of ties, thus assuring a substantial foundation.

Two standard gauge four-wheel trucks with a wide tread wheels and using standard M.C.B. 6 x 11 journal bearings, wedges and couplers are carried by wheel frames hinged to the underside of the main platform. Alternate raising or lowering of these frames through a self-locking worm gear drive places the loader in either operating or moving position.

The 10 x 12 steam cylinders equipped with a patented rotary reverse gear provide an abundance of power to the two car-spotting drums and the propelling mechanism. In fact, speeds as high as eight miles per hour, with a train of cars, is easily obtained.

The most important improvement, however, has been made in the speeding up of the actual loading process through the development of an automatic oil check cylinder.

Shock absorbing or cushioning effect of this devise gives the operator added confidence as an immediate stop can be made at full speed with a minimum of vibration. It also forms an effective lock to prevent swinging when the operating valve is closed. A pivoted turntable, mounted on conical bronze brushed rollers, operating on a steel track, carries the 45-foot steel loading boom, which incidentally, swings out 13 feet 9 inches each side of the track center line.”

This comes from a special edition of The Timberman for the 1932 Logging Congress:

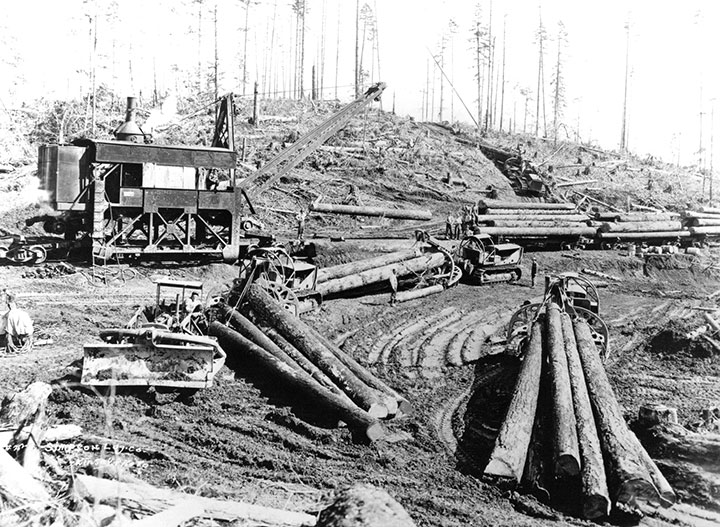

Photo by Clark Kinsey.

“The Washington Iron Works jammer loading for the tractor is equipped with a 10 x 12 engine, supplied by a 54-inch boiler. The 45-foot boom has a lifting capacity of 45,000 pounds. The machine has a duplex style drum control, with two spotting drums and an oil check on the swing. The machine swings a quarter turn 17 feet from the rail. The fuel consumption of this unit is three and one-half barrels a day. It has a capacity of 40 cars in eight hours.”