Introduction

Most home layouts are built by individuals. We have taken a different route. We are a group of senior men and women, ages 70-90+, living in the senior community of Wind Crest about 20 miles south of Denver, Colorado.

Our experience ranges from total novices, to one NMRA Master Model Railroader. Each member has different talents and interests which gives us a great range of options. A couple of examples are the backdrops and weathering which were done by one of our members interested in art. Many of the wood structures were done by a woodworking member. All the wiring, including the Digitrax setup, was done by an electrical engineer.

We started this model railroad in 2013, and essentially completed it in 2018, working 2 hours a day, 2 days a week. It is in a 22½ x 17-foot room with the layout taking up 14½ x 17-feet, allowing for an 8- x 17-foot workspace. There were usually 4 to 8 members at any given day working on the layout. We chose to model in On30 due to our aging eyes and dexterity.

Concept

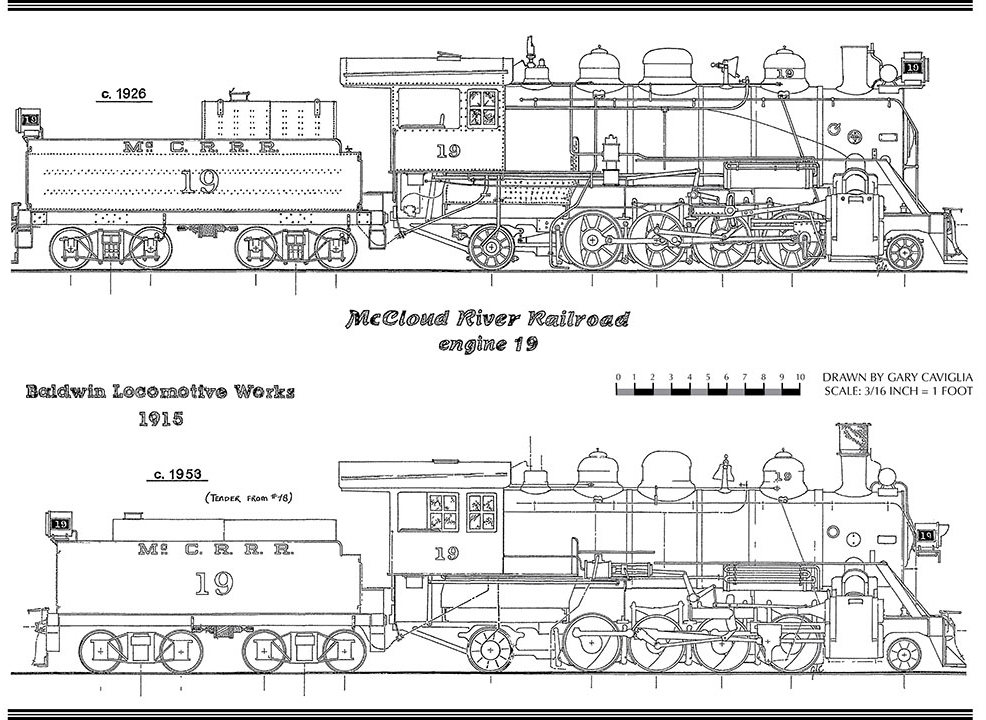

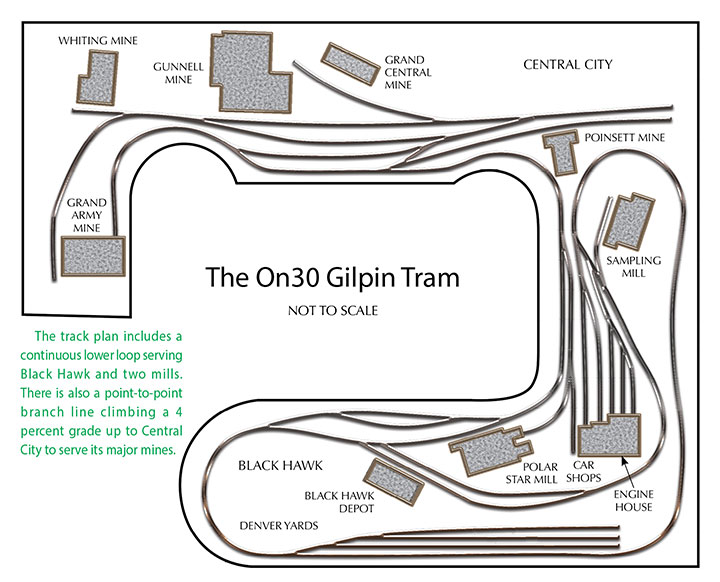

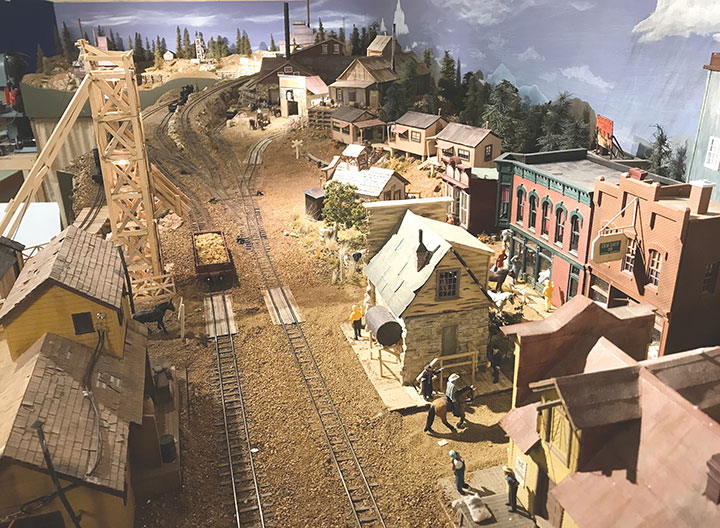

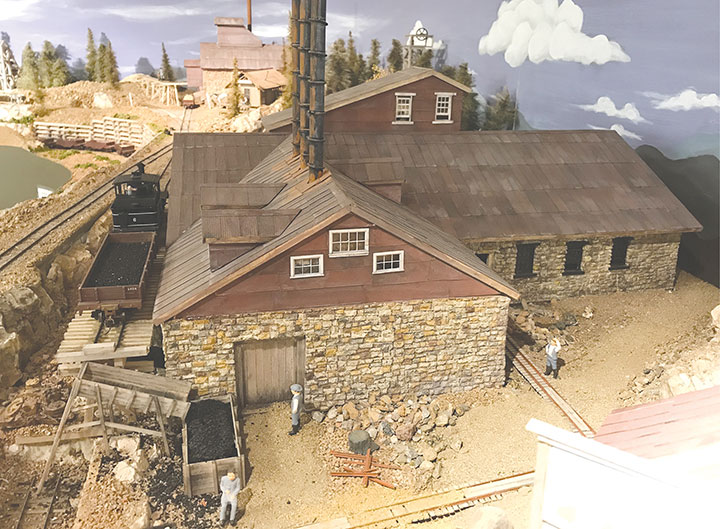

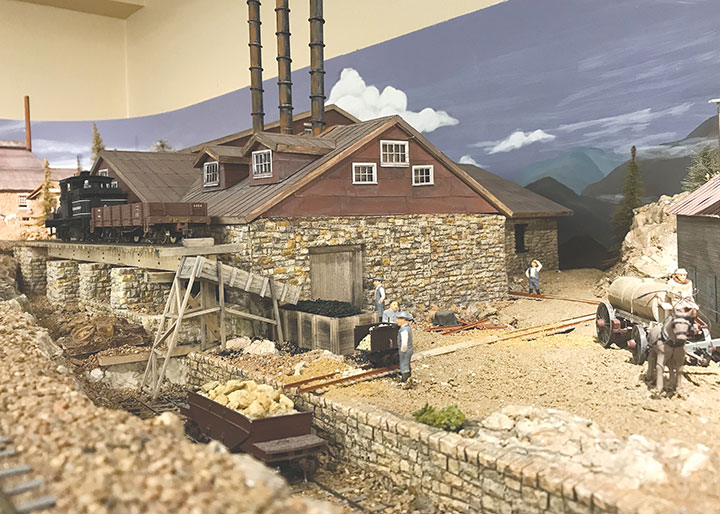

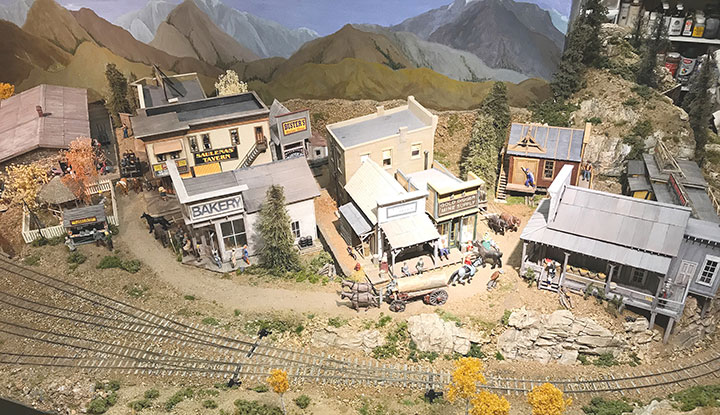

Our concept was to build our version of the 2-foot gauge Gilpin Tram, showing Colorado’s rich mining history as it existed in the early 1900s, but in On30. We chose to model the area between Black Hawk and its mills, and the Mining district above Central City. However, this is strictly a freelance layout where we have included interesting structures from other areas of Colorado.

Track Plan

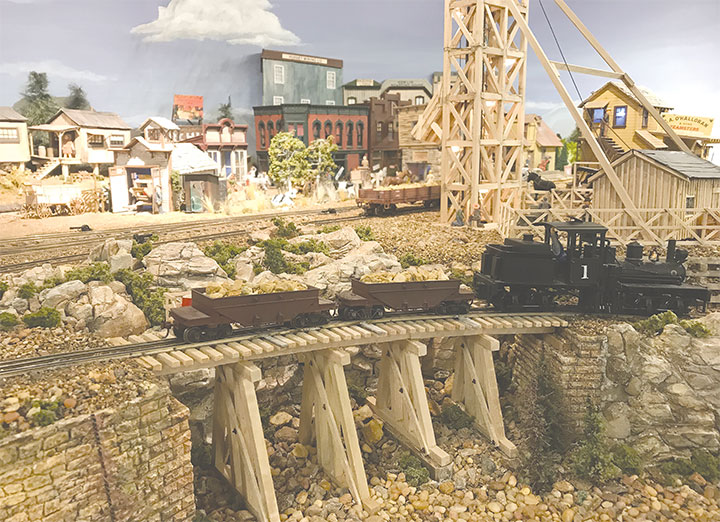

The track plan includes a staging area we called Denver, at 45-inches above the floor. It has a continuous loop that goes through our version of Black Hawk. This includes passing the Black Hawk depot, Polar Star Mill, and the engine facilities, and then back to Denver. In Black Hawk, we have a branch line that climbs a 4 percent grade up to Central City, which is at a 52-inch height. The railroad services the mining district that includes the Grand Central, Gunnell, and Whiting Mines, and ends at the Grand Army Mine.

Construction And Scenery

The benchwork is traditional 2x2-inch legs supporting a 1x4-inch open grid frame with 2-inch-thick sheets of white bead board foam to build the height. The roadbed is ½-inch Homasote glued to the foam base. We used Micro Engineering Code 70 and 83 flextrack and turnouts glued to the Homasote. The turnouts are controlled with Caboose Industries ground throws. All the ballast and dirt came from the Central City area where we made a field trip and brought it home in 5-gallon buckets. Once home, we spent many hours straining it through 5 different size meshes to get it to the proper scale. It was stored in clear plastic containers and numbered by grit size. This made it easy to use as needed.

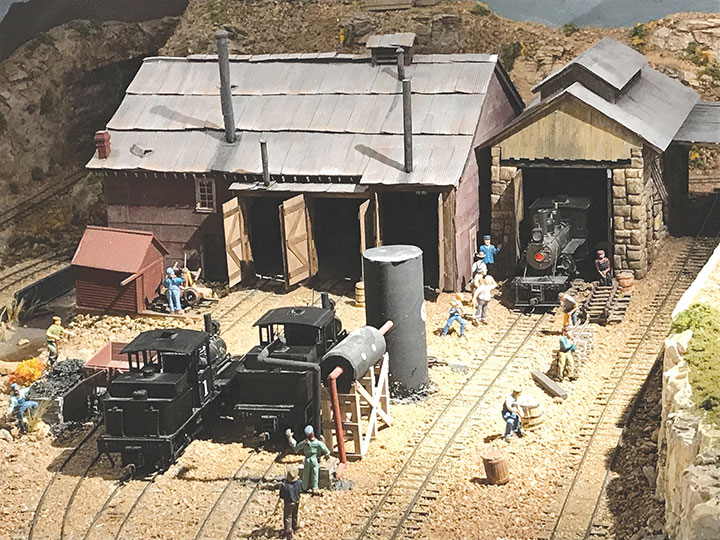

Many of the structures are scratchbuilt using plans from either Mike Blazek or the GAZETTE. Included are the Black Hawk depot, the Engine House, the Polar Star Mill, the Sampling Mill from Idaho Springs, and the Grand Central, Gunnell, Whiting and Grand Army Mines in Central City. We also have a scratchbuilt operating mine in Central City.

The rock-walled buildings including the Black Hawk depot, Polar Star Mill, Gunnell, Whiting and Grand Army Mines were made by pouring Hydrocal into Bragdon Rock Wall rubber molds. When the Hydrocal cured, we cut the door and window openings with homemade shaped hacksaw blades being careful not to break the walls. We then colored them with various liquid stains. The doors and windows are both plastic Grandt Line and laser-cut Wild West Scale Model Builders products. Wild West corrugated material was also used.

The kit-built structures are from many different manufacturers and are mostly kit-bashed to change their appearance and adapt them to their site. Many of the structures have both detailed interiors and lighting.

All our terrain was shaped using the white 2-inch-thick foam, stacked to the desired height, and glued with Liquid Nails which will not attack the foam. The foam was then carved with a hot-wire knife to obtain the desired contours. We then covered it with a layer of Sculptamold and painted it with a variety of earth-colored acrylics. This process worked very well and makes inserting the trees easy.

The landscape, including rocks, ground cover and trees, were either commercial or hand made. Wagons and buggies (no motor vehicles) were from GME. The many figures are mostly hand painted. All the additional accessories are commercial products.

All the backdrops are curved at the corners and were hand painted by one of our members using acrylic paint.

Locomotives And Rolling Stock

All our motive power is Bachmann geared and rod locomotives. Our rolling stock is also Bachmann except for the Grandt Line ore cars that were constructed following a September/October 1998 GAZETTE article by Mallory Hope Ferrell. All these items have been carefully weathered by one of our members using Bragdon Enterprise Powdered Chalks and Stoney Creek Designs Pan Pastels.

Operation

Our operating system is Digitrax DCC with sound decoders installed in all motive power. Now that the construction process is completed, we are in the process of developing an operating system that works best for our members.

The Future

I know I can speak for our entire group by saying “Yes, we are all proud of our finished project, but the very best part of this endeavor was the friendship and camaraderie we now have and will always maintain as we go on to future projects.” And we hold open houses periodically to share our gift with the residents and staff here at the Wind Crest Retirement Living Community.