SOME BACKGROUND

Colorado is perhaps best known for its mountainous terrain. The San Luis Valley in south central Colorado is the setting of my most recent model railroad. This high mountain valley is bounded on the east by the Sangre de Cristo Mountain range and on the west by the San Juan range. The valley floor is relatively flat and sits at an elevation of over 7000 feet. The Rio Grande River flows through the valley. Covering an area of 150 miles in length and about 50 miles wide, the valley boasts some towns with which you may be familiar: Alamosa, Antonito and Creede. But other lesser-known small towns also exist in this area: Monte Vista, Del Norte, Saguache and South Fork.

It is this valley that I chose as a locale for my new model railroad. To utilize equipment and rolling stock from past efforts, I envisioned this railroad as a small 30-inch gauge quarry railway, whose purpose was to gather sand and gravel from the quarry and deliver it to a standard gauge connecting line. I wanted to “get a feel” for the topography of this area, so my wife and I drove there from north Denver. We tied up for the night at a motel in Del Norte. At about 11 pm, we were startled by a thunderously loud Diesel locomotive passing nearly under our window, its powerful engine reverberating and pulsing off the motel’s brick wall. As we discovered later, this train makes its way up the valley at night to avoid automobile traffic at the grade crossings. It visits various small industries and locations in the valley, delivering empties and pulling out loads. This is the San Luis & Rio Grande Railroad, and is the last remaining vestige of the D&RGW in the valley. I now had the perfect prototype to serve as the standard gauge connection to my narrow gauge quarry railway. As we drove down the valley, I stopped frequently to take photos, including a series of landscapes, I hoped would serve as a geographically correct backdrop for my railroad. In addition, I discovered to my surprise that there is an old, abandoned quarry near Del Norte, although it produced cut building stone, rather than sand and gravel, and never had a railway.

THE LAYOUT

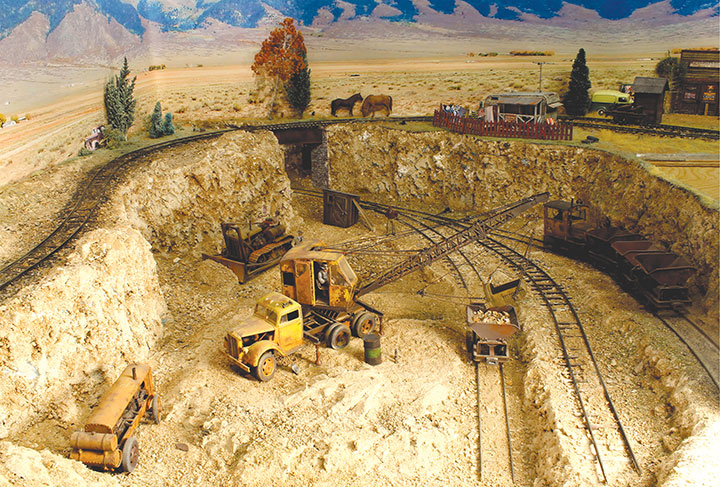

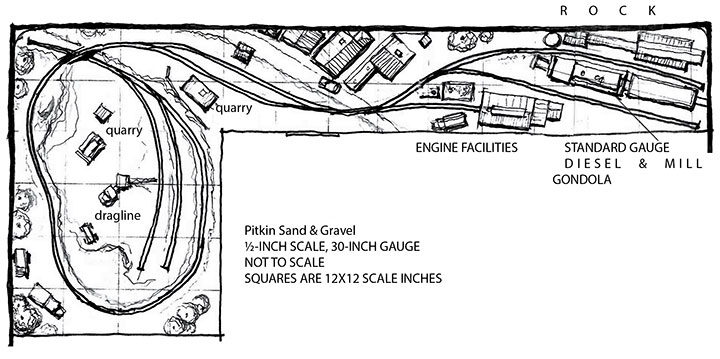

Inspired by a Tom Yorke track plan, I designed my layout to fit in a confined area of my home, so it is of modest size, despite being ½-inch scale. Consisting of a quarry and track leading to a standard gauge interchange with a small engine terminal, I wanted something I could have up and running quickly. The quarry itself was the most challenging and interesting segment to construct. I based the design of my small quarry on several quarries I had researched, as well as the Tom Yorke track plan, featuring track that winds tightly down to the floor of the quarry, where tipper cars can be loaded. I used the cookie cutter technique with 3/8-inch plywood to construct the basic sub-roadbed here. After installing sufficient risers to support the plywood, I installed O gauge flextrack. O gauge track becomes 30-inch gauge in ½-inch scale. The curves and grades here are outrageously sharp and steep, but this is an industrial railroad with tiny equipment. This approach mandates that all my turnouts be scratchbuilt since standard O gauge turnouts are much too long and shallow. Simple Caboose Industries ground throws were utilized on all turnouts, in keeping with the industrial nature of the layout. These throws look quite good in the larger scale after a bit of weathering. Following completion of the track and wiring, I inserted random-thickness chunks of pink foam between the layers of plywood sub-roadbed to form the basic walls of the quarry, securing them in place with construction adhesive. Spackling was used to fill any gaps between the foam pieces. Then I applied a thick coat of earth-colored latex paint, and literally threw sand onto it while wet. Additional small rocks were added later and adhered with white glue.

The remainder of the layout is constructed with L-girder framing, topped with plywood or pink foam. I found a local source for suitably sized gravel and earth ground cover, and this was adhered with white glue.

LOCOMOTIVES & ROLLING STOCK

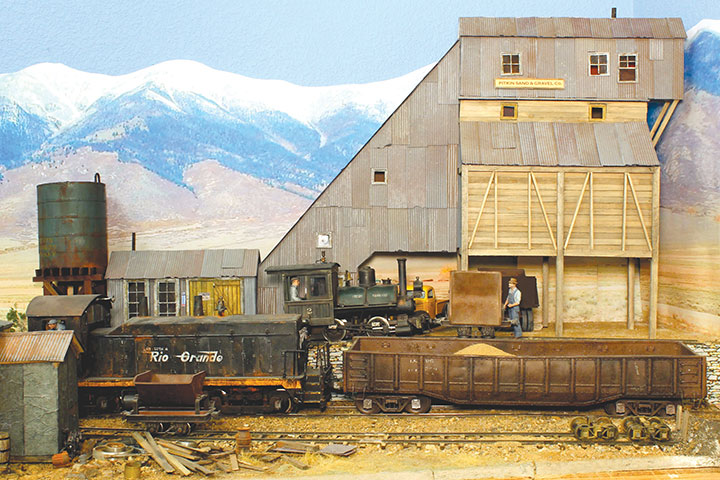

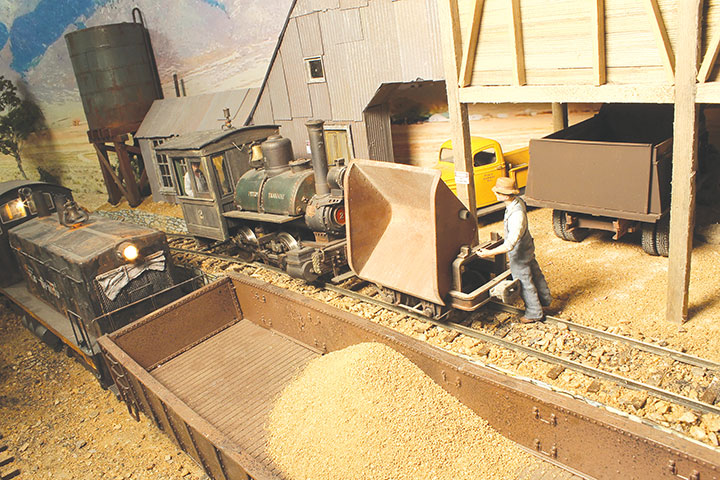

Since ½-inch scale, 30-inch gauge is not a common scale/gauge combination, I had to scratchbuild or kit bash most of my locomotives and rolling stock. The locomotives include a modified O scale Diesel by Atlas, a European Regner industrial Diesel, and a Brookville industrial locomotive from Tom Yorke. I constructed a new larger cab for the O scale locomotive and added various ½-inch scale detail parts. Similarly, I modified the Regner locomotive to have a more American appearance and re-gauged it. In addition, I scratchbuilt a freelanced 0-4-0T tank steam locomotive, designed to resemble a Porter product. I use 1:29 scale equipment to represent standard gauge, even though the scale and gauge are not exactly accurate. I enjoy seeing the contrast in size between the large standard gauge equipment and my tiny narrow gauge gas mechanicals and rolling stock. I also scratchbuilt a string of 4-wheel tipper cars from styrene and ABS for use in the quarry.

I acquired a USA Trains EMD NW-2 Diesel locomotive and a mill gondola to serve as the standard gauge connection. These were both detailed, re-painted and weathered to replicate well-used and tired equipment. I lettered the locomotive for the San Luis & Rio Grande RR. There was never any intent to operate these items, although I do have operational lights on the locomotive and a sound chip of an idling Diesel. They sit on a siding, waiting for the gondola to be filled from the quarry tipper cars.

STRUCTURES & VEHICLES

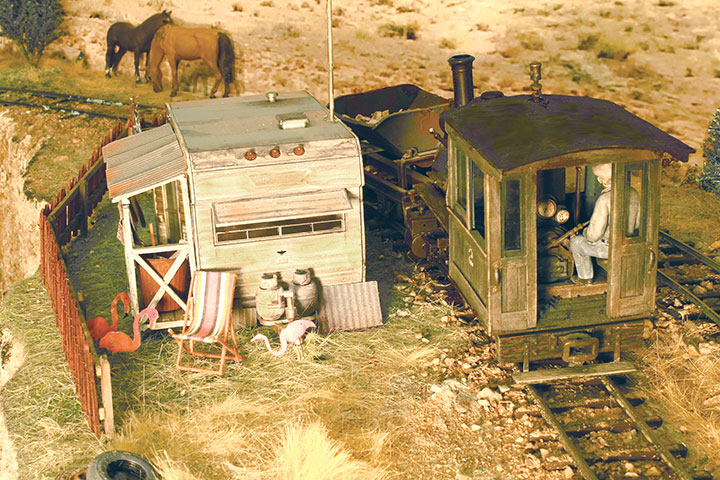

All structures are scratchbuilt, ex-cept for a die cast camping trailer which serves as the home and office of the quarry manager. I weathered and detailed this item, fitting a TV antenna, corrugated skirting under the trailer body, an added wood porch, a clothesline, pink flamingoes, and scratchbuilt camp chair.

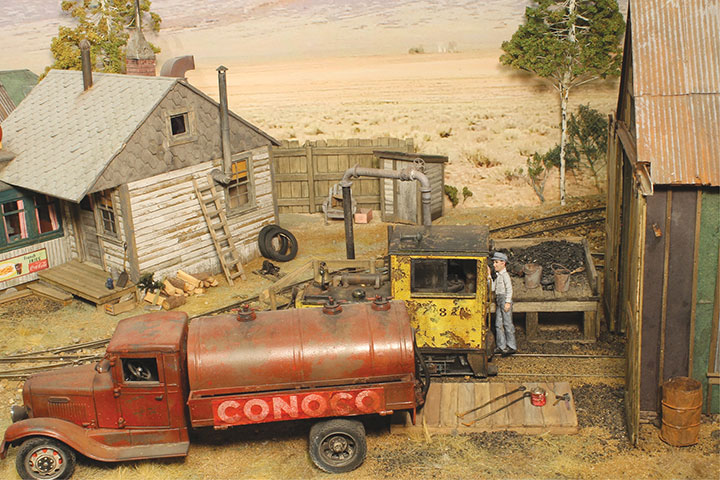

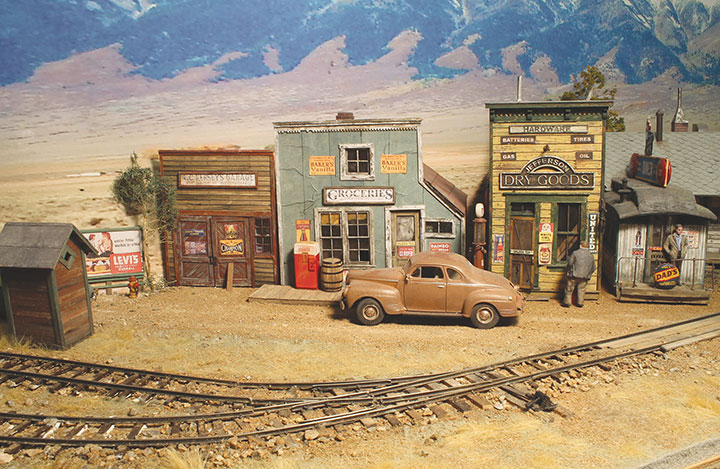

There is a small village on the layout, with only a few structures. The grocery store is based on a Randsville, California, prototype and the derelict Jefferson Dry Goods store is the second iteration of this free-lanced building. The original was my first large scale structure, scratchbuilt some thirty-five years ago. This replica is a very limited edition lasered kit from Phil Dippel. The diner is an interesting structure based on a unique prototype building (although not a diner) that exists a few miles from my home. I have been unable to determine the origins of this wonderful little gem, but it consists of a vintage wood railroad coach attached to a small cottage. I decided to turn it into a diner with the assistance of a Bachmann coach body. Interior lighting and complete interior detailing make it an attractive feature on the layout. Lighting in my buildings was done with LED units from Evan Designs.

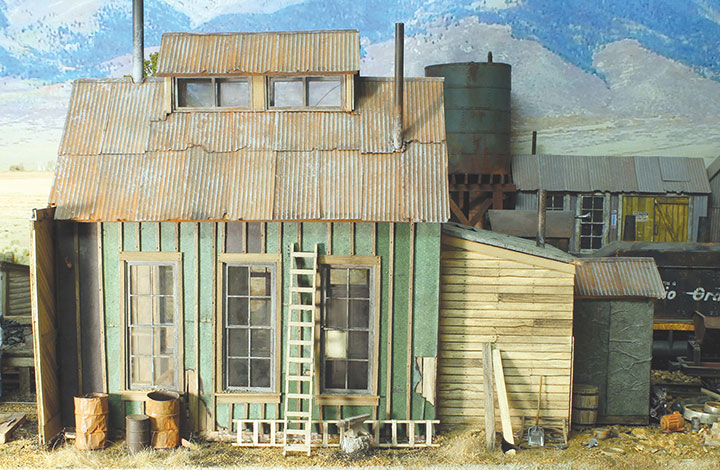

Other scratchbuilt structures include an engine shed and rock crusher. The engine shed is impossibly short, but then, so are my locomotives. An abbreviated version of a C&S coaling platform and water plug based on a Leadville, Colorado, prototype, serve to fuel the steam locomotive. An old fuel tanker truck provides fuel for the gas mechanical locomotives. The rock crusher building was cobbled together with a basic structure of Task Board overlaid with paper corrugated metal sheathing.

Various plastic kit and die cast vehicles were used on the layout, all weathered and modified in some way. I enjoy adding license plates for my vehicles, correct for the period.

SPECIAL ANIMATED FEATURE

I wanted to be able to load tipper cars in the quarry. I suppose it’s desire to return to the sandbox at my advanced age. I envisioned a fully operational truck-mounted dragline. However, my skills and mechanical knowledge were not up to the task. I am extremely fortunate to have a fellow modeler in the area, named Scott Betts, who happens to be both an excellent modeler and a competent mechanical engineer. He graciously agreed to give the project some life and designed an intriguing under-the-table mechanism that enables the dragline model to do about everything a prototype does. But that wasn’t quite enough for Scott — he also installed sound! It still amazes me to be able to operate the controls of this contraption and load tipper cars. The basic dragline model is a die cast product from SpecCast, the Bantam C-35 Dragline, with the base chassis and tracks removed, mounted on a Tamiya Opel plastic truck chassis. My grandson, Grant Dunbar, 3D printed the screw jacks and shovels. The portable compressor and Caterpillar bulldozer in the quarry are models I built many years ago and re-used here. The compressor is totally scratchbuilt from styrene, basswood and brass, and the Caterpillar bulldozer is a die cast Conrad product that I detailed with an overhead blade mechanism.

SCENERY

The major scenic item on this layout is the photo backdrop. It was necessary to establish the locale. After a couple of failed attempts to piece together something I printed myself, I went to a Staples store with my photos, and they were able to stitch them together and print them out on a continuous 22-foot-long roll of canvas-like paper. I painted the wall surface behind the layout sky blue and cut off the sky portion of the photo mural. With the mural installed on the wall, the layout is significantly expanded visually, and I am totally pleased with the final product.

I attempted to use static grass for the first time, with mixed results. In the end, my ground cover consists of some static grass interspersed with ground foam and hand-planted weeds and shrubs. An enormous double-trunked Ponderosa pine, fabricated by Will Cheshire, majestically occupies one corner of the backdrop. Other trees are made from various live and artificial plant materials, all dirt and rocks on the layout are the real thing, gathered near my Colorado home.

OPERATION

Operation is simple and consists of sending a locomotive down into the quarry to pick up a short string of loaded tipper cars, while dropping a few empties. Two sidings in the quarry assist in keeping empties and loads separate. The loaded cars are pulled out of the quarry and can be dropped at the passing siding near the quarry office for later delivery to the standard gauge connection. Tipper cars can be pushed up the embankment to the rock crusher and dumped there or can be pushed further along the embankment to be tipped into the standard gauge gondola. When the gondola is full, the body is lifted by hand off the fixed stationary trucks and dumped back into the quarry, and the cycle repeats.

CONTROL

My trains are run on simple DC power using a tethered throttle from GML Enterprises. Its central location on the front of the layout allows me to reach all the ground throws as I operate the trains.

CONCLUSION

This has been a very satisfying project, and I thank those who assisted in its construction. Having friends to share the hobby is an enriching experience. In addition to those named above, Gary Young and Steve Pollak were very helpful in completing this layout.