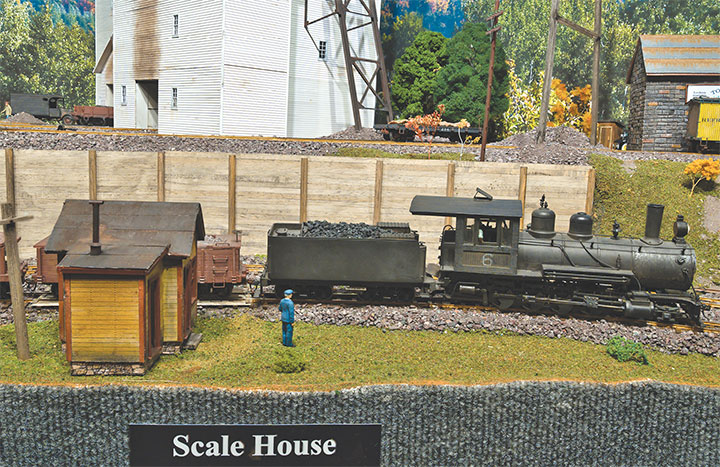

The operator at the Quincy scale house calls the office in the back room of the roundhouse and the Finnlander says: “This is Thorvald Kaminen at the scale, Train 1, Engine 6, seven cars—four loads for mill number one at 225,200 gross pounds, and three loads for mill number two at 169,100 gross pounds. Ready for departure at 6:10 AM.” Clerk Sven Svenselrud replies, “Gottcha down on the sheet there fer sure hey.” And thus begins the run of the first rock train of the day on Pat Thoney’s Quincy & Torch Lake Railroad where it is forever October of 1942. We are visiting the Upper Peninsula of Michigan where the residents are known as Yoopers, and their dialect is an endearing part of the culture. We will follow Train 1 in our ’37 Chevy and shoot photos of whatever railfan opportunities we find.

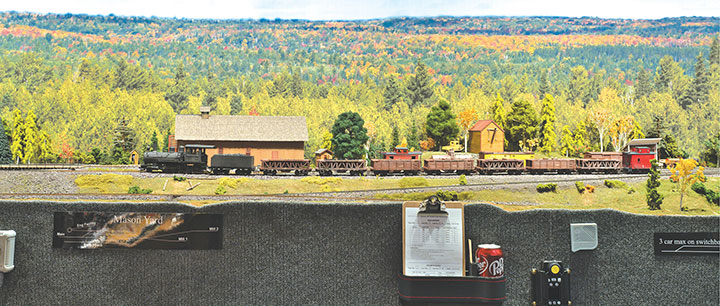

Train Number 1 will haul its seven cars for six miles down to Mason and shove them into the two mills as the Trainmaster has directed. The Trainmaster has also decided that Train Number 1 will bring two cars of coal from Mason back to the Quincy Mine (Train Number 2 on the return). So, after delivering the seven loads of copper rock—they call it rock, not ore—Engine 6 will take two empties down to the massive coal dock on the shore of Torch Lake. There the empties will be switched for two cars of coal, and along with five empty rock cars, will be the consist for the return trip to Quincy. Hence the apt title for Chuck Pomazal’s book about the Q&TL, Rock Down, Coal Up (available from the Quincy Mine Hoist Association, www.quincymine.com).

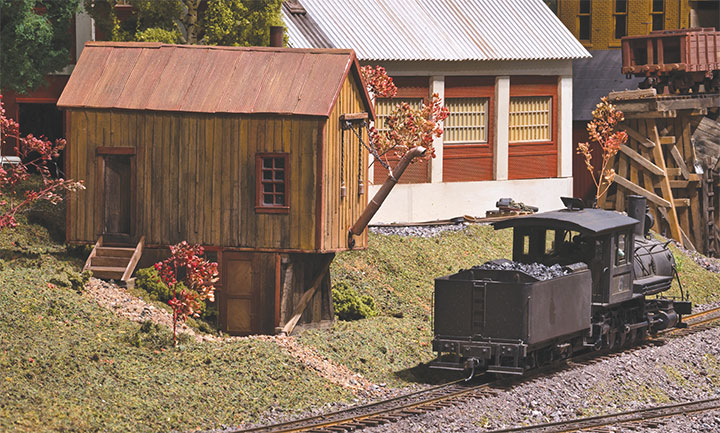

Pat’s layout is an exquisite On30 model of the 3-foot gauge Quincy & Torch Lake. Superintendent of Motive Power, Al Peeso, has built all six Q&TL engines. To construct each loco, Al started with a Bachmann or Broadway Limited On30 model, in some cases used only the running gear. The engines are such extensive kit-bashes that they are to a great extent scratchbuilt. I covered the construction of three of the locomotives in the July/August 2018 GAZETTE. We’ll present the other three in a future article.

But this article isn’t about the layout, it’s about a day in the life of the layout. Model railroading is all about preserving the fascination of railroading in miniature. For most of us, that focuses on the motive power. Obviously, we also preserve in model form the rolling stock and structures. Some of us go to the extent of preserving not merely the railroad, but the geography and physical manifestations of the culture that provided the context for the railroad. The geography and the culture—in model form—are a big part of the spirit of the thing.

Just as we can preserve railroading via scale models, we can preserve railroading through simulation of a rail-road’s operations. Operations is business simulation and historical reenactment. In operations, the locomotives and cars, along with the structures and scenery, all become props in the greater exercise of bringing the railroad to life—and allowing us to be part of that life. Admittedly, this simulated experience must be different from the prototypical life. We can’t go back in time. We don’t get cinders in our eyes up on a swaying car top, nor do we sweat profusely in a stifling cab. We won’t get killed if we make a big mistake—though we could offer that possibility to operations skeptics if that would give them a more palpable stake in the game! Operations isn’t the only way to enjoy model railroading, but it sure is one of the ways.

ROCK TRAINS

The major role for the Q&TL was to take copper-bearing rock from the two mine shaft houses on Quincy Hill down to the two mills on the shores of Torch Lake. For every six or seven cars of rock that go down to the mills, two or three cars of coal come back up. The Quincy coal dock is massive with three movable cranes to unload coal from large lake boats and store it in the huge shed, and later load it into the rock cars of the Q&TL. The engine that brings a train down to Mason is also the engine that switches the mills and the coal dock in preparation for the trip back to Quincy.

Pat follows the prototype practice of numbering the Mason-bound trains in sequence. First rock train of the day is Train 1, and its return trip is Train 2. The second rock train of the day for Mason is Train 3, and so on. For the mills to function for a day, they need three trains of rock, though that can vary as the General Manager (Pat) decides. The pair of 2-8-0 locomotives usually handles the rock trains.

SWITCH JOBS

In prototypical fashion, not all six locomotives run each day. Daily switching on Quincy Hill is handled by a pair of 2-6-0s. Operating within yard limits, the two switch crews keep out of each other’s way. An interesting prototype, the Q&TL had a switchback at both ends of the railroad, and so does Pat’s layout. At each end of the railroad, the switchback limits a move to a locomotive and three cars. The main Quincy yard is by the roundhouse. A switchback goes up the hill to the mines. Mine structures include shaft houses Number 2 and Number 6 (the last two used by the prototype). Each shaft house is accompanied by a hoist house that is fed by a coal-consuming boiler house. Facilities on the hill also include blacksmith and machine shops, warehouse, locomotive coaling chute, Earl’s Fuel, ice warehouse, and commercial coal facility. At Mason, a switchback goes down to the coal dock and standard-gauge interchange.

Switch crews go about their work taking cars of coal where needed, taking empties to the shaft houses, and pulling loads from the shaft houses to take down to the main yard where they make up mainline trains. The switch crews place removable loads in rock cars at the mines. Rock train crews remove loads from cars at the mills and place them in a special container—an antique railroad spittoon. Operations with a grin!

LOCAL FREIGHT TRAINS

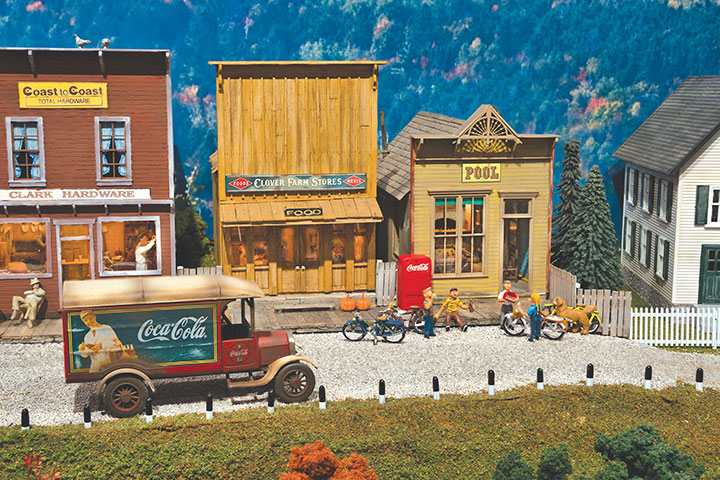

Once a day—but sometimes not every day—a local freight is run. This train handles the few cars of interchange transfer freight that come off the standard-gauge connection on the Mason lakefront. These are cars of merchandise and fuel for the sidings at the intermediate village of Paavola and for Quincy. A 2-6-0 handles the local freight.

PASSENGER TRAINS

The first and last trains of the day are passenger runs. The long side-door caboose is used in conjunction with one of the short cabooses. This was sometimes done on the prototype. The model Q&TL awaits completion of the distinctive caboose-cupola coach.

The passenger trains run for the benefit of Quincy personnel and company mail. The Quincy Mining Company owns the common carrier Q&TL. Managers and technicians are often needed at the opposite end of the railroad, and some workers at the Mason mills commute from Quincy.

PERSONNEL AND PAPERWORK

In addition to General Manager/Dispatcher/Trainmaster (Pat), a typical day’s operation on the Q&TL involves a crew of four or five. At a given moment, the Q&TL is likely to have two switch crews working at Quincy, and two rock train crews at work out on the line. In addition to those four, another crew member or two can be on hand to alternate jobs or to be part of a two-man train crew. In off moments, one can go to beans at the munchie table and play railfan.

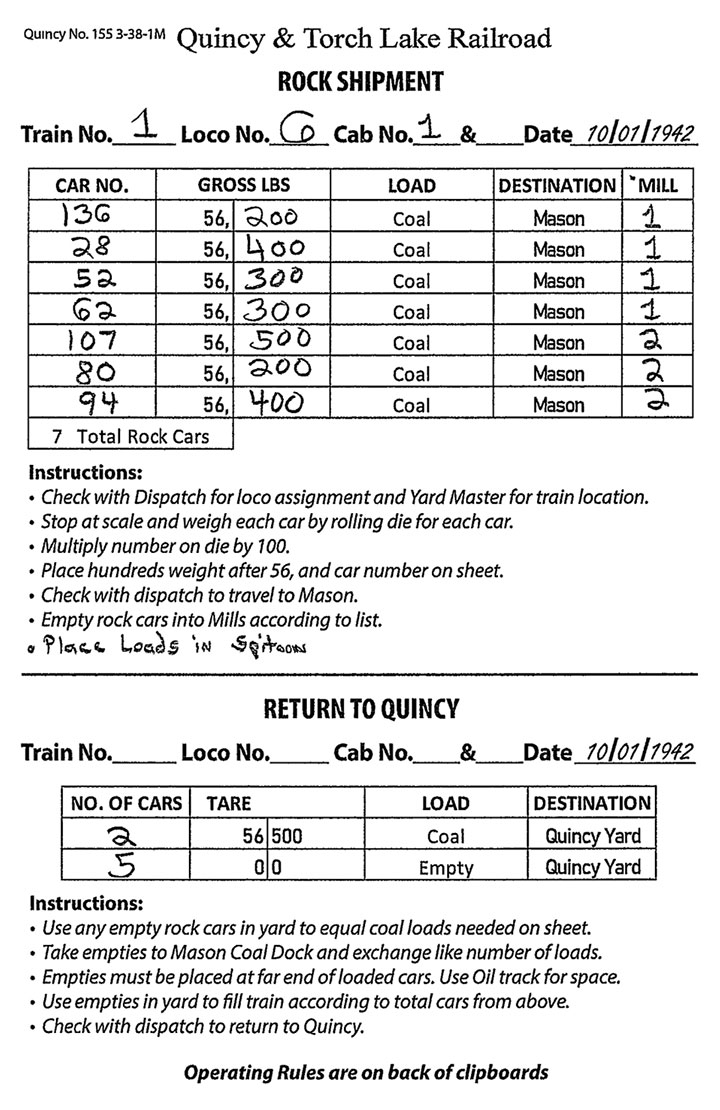

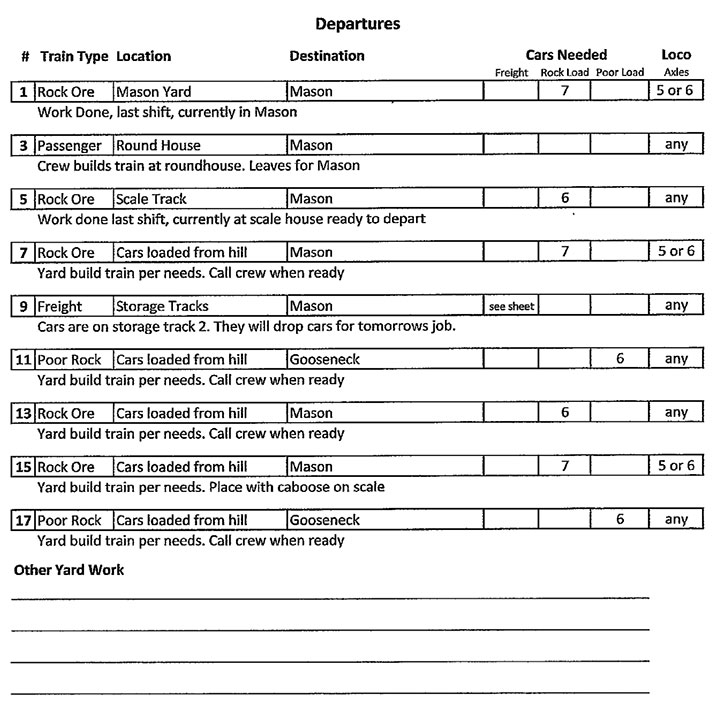

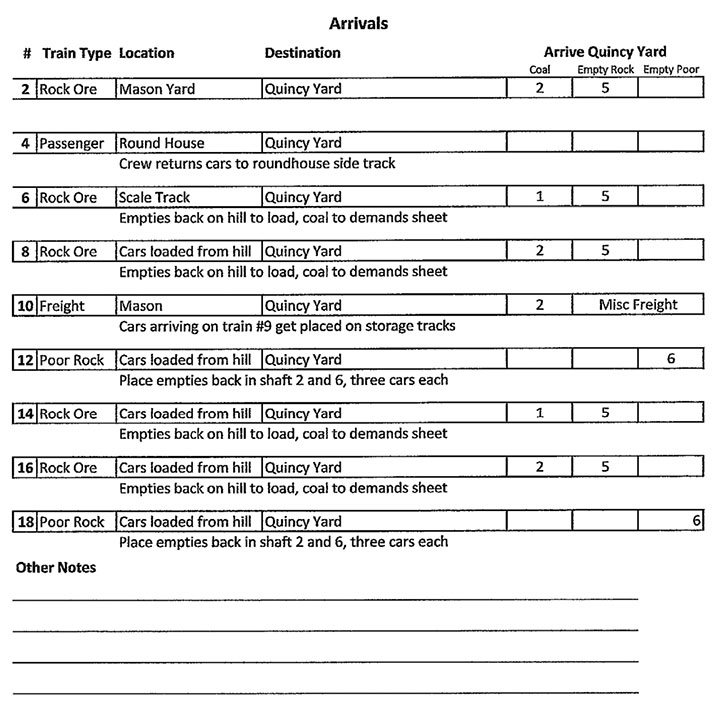

Rock trains are governed by the form in Figure 1. The form is very much like the prototype form that accompanied each train. “Instructions” are included for both legs of the run to tell “newbies” what to do—information that the prototype daily workers would know by heart. Figures 2 and 3 are descriptions of the trains that arrive and depart Quincy.

To lend a note of realistic function to operation of a rock train, each car is stopped on the scale. A container on the fascia holds a die which is rolled to indicate hundreds of pounds, and that number is written after 56,000 to list the gross pounds of rock in each car. For example, a roll of the die resulting in three dots would indicate a carload of 56,300 pounds. The form also indicates to which of the two mills each car goes. The “return” portion of the form indicates number of cars of coal and number of empties in the up-bound train. I was railfanning down at the scale house and heard fireman Ole and engineer Sven talking. Sven said he was getting divorced. Ole said he hoped Lena would have enough to live on. “By golly,” said Sven, “it’s all good. The judge said he’s giving Lena $300 a month; maybe he’ll give me a few bucks occasionally, too.”

TRAIN AUTHORITY

At the start of the operations day, Trainmaster Pat assigns two people as switch crews on Quincy Hill, and they go to work. The last task of the switch crews each day is to prepare an outbound rock train which is placed in the yard for movement the next day. So, when the day begins, a mainline rock train is ready to go, and the switch crews spend the day keeping them coming. When a mainline train is ready for departure, the switch crew informs Dispatcher Pat, and he assigns a road crew. Train orders are spoken and indicate whether the run is straight through to Mason or includes a meet at the intervening siding at Paavola.

A departing road crew asks permission from the yardmaster to thread his way out of Quincy. The yardmaster at any moment is whichever switch engine crew will be affected by a mainline train. Mainline trains report their locations via telephones located in the roundhouse, scale house, Paavola, and a telephone shack in Mason.

An enlivening feature of the Q&TL is location-specific sound. There are push-buttons along the fascia that operators can activate to play sounds for water tanks, coal chutes, and the like.

A train running from Mason back to Quincy, stops at the Quincy scale house. The arriving road crew obtains instructions from the yardmaster as to which tracks to occupy.

RAILFANNING

Railfanning the Q&TL is a great experience! As an intense HOn3 modeler, I stand in admiration of this On30 layout. The detail is big enough to seem big. The wheels go “clunk” on rail joints. The sounds are robust and throaty. With DCC, lights, sound, and keep-alive, there are few-to-zero distracting mechanical hiccups.

More than mere fun, operations on Pat’s Q&TL is a heart-warming mind-trip back in time to the urgency of World War II when an aging 1890 physical plant strived mightily to play its vital function in the survival of the nation. It’s the last hurrah for a little-known antique railroad that is operating in a remote and geographically beautiful place. But while the lights are on in Pat Thoney’s train room, all is well on the Q&TL!