Some Background

Deep down in the canyon between the Cat Shed and the garden fence, in the Condo Canyon, resides the Redgate Ore Processing Mill. This is the story of how it got there.

My Cumbres & Cat Shed Railroad (C&CSRR) is an On30 narrow gauge short line located in a North Yorkshire garden. The system is battery on board (dead rail) with battery powered radio-controlled locomotives. An article in the 2021 edition of Garden Trains Annual (page 84 to 90) describes the railroad as it was in 2020.

The line, like many other narrow gauge and short lines owes its existence to the carriage of minerals. Originally this flow was from an ore tipple at Rockery Ridge, served by an even narrower gauged (On2) tramway out of a mine adit in the garden rockery, north via Donkey Corners yard to the mythical Buck Hollow.

One of the first buildings constructed for the C&CSRR was a Wild West Scale Model Builders’ (WWSMB) Black Hawk, Colorado, trackside warehouse.

Whilst searching the WWSMB website I came upon the section on stamp mill parts (http://www.wildwestmodels.com/products/products-o-machines.html). As a former mining engineer, I was immediately attracted to the beautiful items on display. However, back in 2016, I had other priorities for the model railroad budget and US$120.00 for a ten-stamp battery of California stamps was out of range. This discovery was filed away for another day.

In the summer of 2020, we had some trees cut down by the garden fence and the rail tracks were extended beyond Walkabout Gap depot, around a curve and into the space between the fence and the Cat Shed, known now as the Condo Canyon. In the canyon, the tracks fan out with two leading to a turntable and the third acting as a siding. The primary purpose of this extension was to provide enhanced operating potential and a final destination and turning facility for the El Gato varnish train. However, memories of those stamp mill parts began to resurface.

So, I re-visited the WWSMB website and on the structures page, along with the Atlantic Cable Mine which graces our indoor switching layout (On30 Annual 2021, pages 90 to 93), was the Little Red Mill (kit #823). This kit was out of stock but the associated photos gave an idea of what might be. So, I decided to scratchbuild the mill and detail the interior with parts from WWSMB and Wiseman Model Services. The name, Redgate Mill came from a corn mill located in the Weald of Sussex, southern England.

Building the Mill

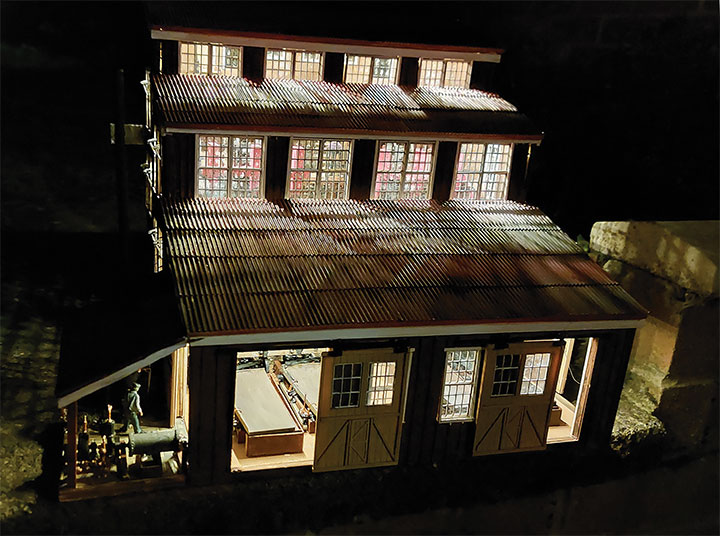

All lineside structures on the C&CSRR are stored indoors and taken out to the garden for operating sessions. So far, the structures have been placed on the ground directly beside the tracks. In the canyon, due to the landform, the tracks run on benching. Old style ore mills were often built on hill sides to allow gravity to help the process flow, so the sixteen inches between the top of the benching and the area below it would allow scope to develop the mill below the line of rail. However, this meant that the mill structure would have to be strong and capable of being attached to the benching.

The base of the mill, is 12-inches long by 13-inches wide with a 3- x 4-inch machinery shack. The rear wall was made from 5/8-inch-thick plywood braced with strip wood and angle brackets. Coach screws and wing nuts are used to attach the mill to the benching.

The initial plan for the mill was that it was to be a single stream affair with one stamp battery. The process flow sheet was designed to be as realistic as possible and to utilize all the parts available from WWSMB. Mike Pyne, owner of WWSMB was kind enough to send several parts that were not actually available at the time.

Construction commenced by scratchbuilding an ore bin from Mt. Albert Scale Lumber to store the ore brought to the mill by rail for processing.

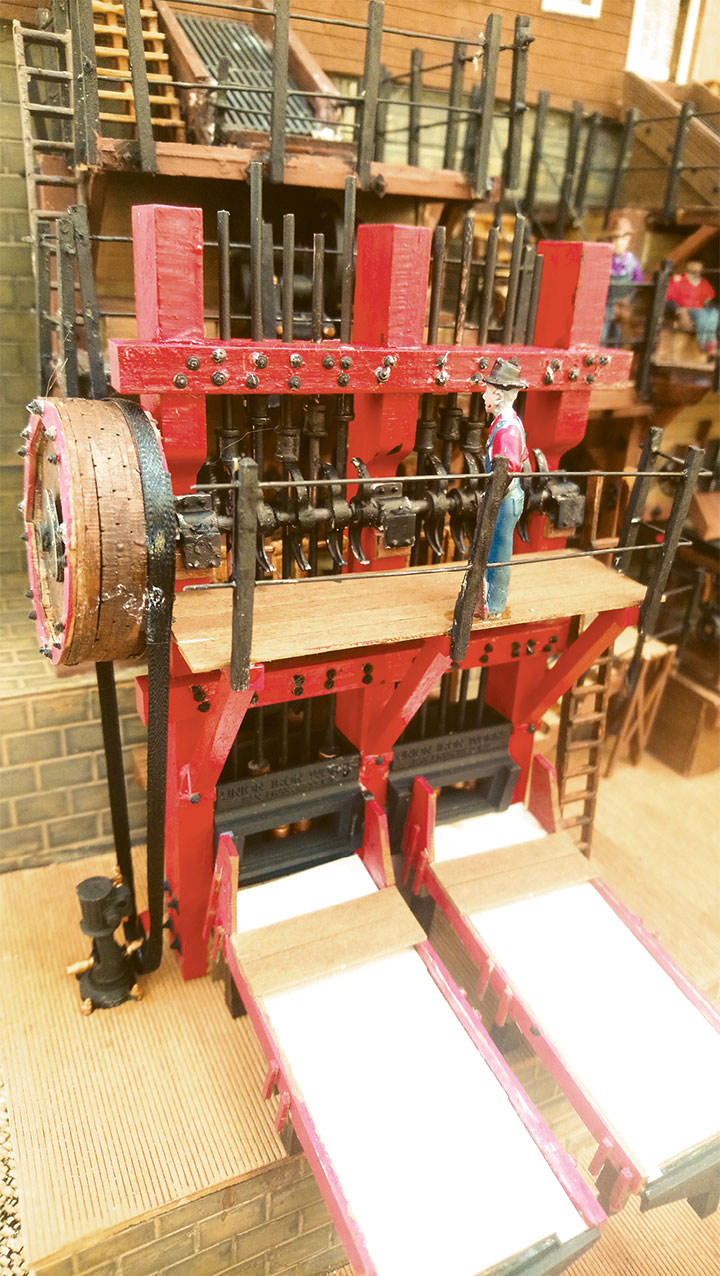

After completing the ore bin, I assembled the WWSMB Challenge Ore Feeders (#M4), ten headed Californian stamp mill (#M6) and two Wilfley shaking tables (#M7).

With the machinery complete, I started on the mill building. Then I realized there was room for another set of stamps.

The sides for the mill building were cut from 3/16-inch plywood, covered on the inside, with scribed sheet wood and on the outside with battens. Window and door openings were cut out using a hobby knife. I cut the openings by first drilling holes in each corner of an opening. Glazing was glued into place with Canopy Glue to avoid the fog effect brought on by super-glue. The wood parts were joined using an aliphatic resin.

Handrails guarding platforms and stairways were made from spent match sticks and wire left over from building rolling stock. Nothing goes to waste on the C&CSRR. Stairs and ladders are from Kitwood Hill Models.

To fit the mill into the canyon, and allow the train operator to pass safely to the turntable, the width of the mill was restricted to thirteen inches. The discharge from the amalgamation tables had therefore to be superimposed over the Wilfley table drives. To allow the detailed drive mechanism to be visible, the walkway around the amalgamation tables was made from mesh.

Power for the mill is generated in the adjacent machinery shack with a stationary boiler to raise steam and a generator to provide electricity for lighting. Stamps, Wilfley tables and the generator are driven by small vertical steam engines.

See https://wisemanmodelservices.com.

The shack also contains the clean-up barrel, used to reclaim the amalgam, and the boiler feedwater pump.

Lighting within the mill building is provided by battery powered LED strips which are attached to the insides of the roof units.

With all those expensive detailed parts, the total cost of my mill was around $725.00 U.S., close to an On30 Mountain Models MI K-37, so I decided that the three main roofs should be removable allowing all that expensive detail to be appreciated. The roofs, with the exception of the machinery shack, are simple sheets of 3/16-inch plywood covered with corrugated material from Kitwood Hill Models.

The corrugated material was sprayed with acrylic red paint and then toned down with black spray. The roof for the machinery shack has trusses, as the underside can be seen, but the main roofs are plain. The boiler smokestack is 8-inches tall and ¼-inch in diameter. Positioning the hole for the boiler stack was tricky, as was the cutting of the hole through the corrugated. I finally used a series of templates, first paper, later card, and a wood drill.

Redgate Mill was my project for the winter of 2021/2022. Work started, building the first pair of Wilfley tables in September 2021, and ended with the second pair in February 2022. Actually, the project isn’t really over. More mill staff are to be employed. All figures are from https://www.paintinghistory.co.uk/omen-1-48.

I have also built a standard gauge boxcar that can be placed on a short section of track in front of the mill. The car is an interesting comparison with the narrow gauge up above.