My wife, Pat, and I stood at the bottom of our basement stairs. To our right was the recently completed crew lounge. To our left was the empty train room—a blank canvas, as it were, upon which to paint a layout. She said to me, “I suppose right here will be the end of a peninsula with the track running around the edge of it!” I replied rather mindlessly, “I suppose so.” She said, “Everybody does that; it’s a cliché in model railroading! Your peninsula will be nearly 40 feet long; you’ll never miss three feet of run, move the turnback loop away from the end of the peninsula and mask it in a cut; narrow the end of the peninsula into a teardrop which will be eye-appealing and improve traffic flow into the aisles. Then build your signature mining scene right here where it will be the first thing visitors see.” This from the astute eye of a lady who has never built a layout but has visited many. I had to agree with her on all counts.

While I purport to be modeling the Rio Grande Southern—and mostly I am—this scene is pure fiction. I built it to be representational of mine scenes across Colorado. I named the place Silver Spur. In building the mine and mill I followed a prototype—sort of.

Centennial Mill

On a visit to Georgetown, Colorado, in 2010 I noticed again the Centennial Mill at the south edge of town. I’d given it scant attention on many Georgetown visits over the years, but suddenly I realized how rare a Colorado ore-reduction mill has become! The first photos show the mill. It’s rare that a mill has been maintained. Apparently about half the corrugated siding has been replaced to the extent that the original lettering is barely decipherable.

I never intended to model the Centennial Mill per se. I didn’t bother to take any measurements. I figured I could calculate dimensions off my photos and good guesses would be close enough.

Silver Spur Mill

My model mill, Silver Spur Mill, is based upon the Centennial Mill. It’s not a scale model of it. My overall objective in building my RGS layout is to capture the spirit of the prototype. I consider the depots to be focal points, and so all five of my RGS depots are as faithful to prototype as I could build them. Beyond the depots, some things are “pure” prototype, and some are representational fiction. I’m trying to portray 30-40 miles of prototype in 3-4 scale miles—something’s gotta give, as the old song says.

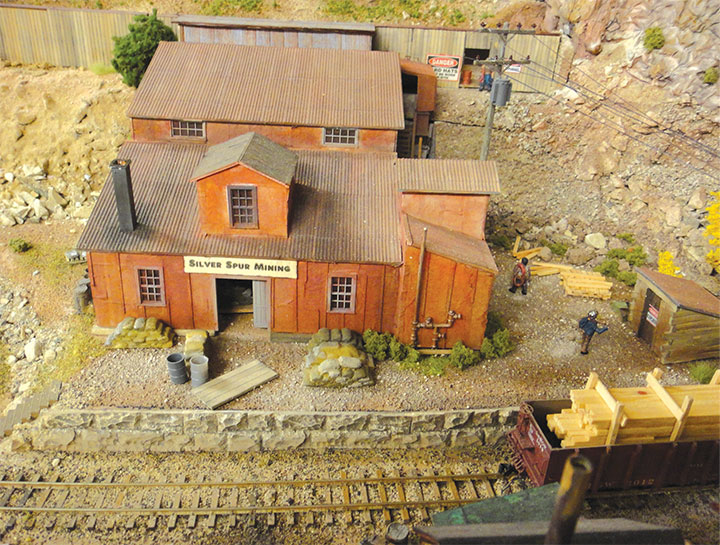

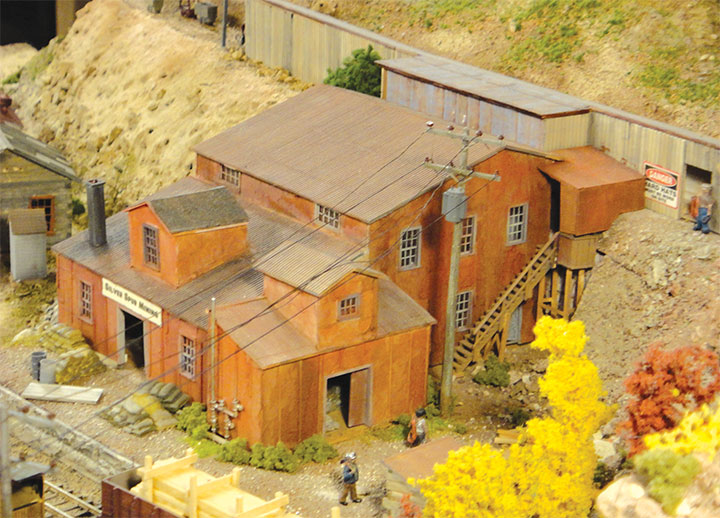

Three photos show my model of the Silver Spur Mill. To build it, I pawed through my boxes of window castings until I found some that looked like the Centennial windows. I started at the corner of a sheet of paper and placed the windows in an arrangement that looked like the front of the Centennial. I guessed that the center door was eight feet square. I laid a scale ruler under my row of windows and concluded that a structure width of 36 feet would work. Looking at the prototype photos again and trying to keep a sense of proportion, I quickly concluded that the building’s footprint would be 36- by 48-feet.

For structure height I felt that the front wall should be ten feet high. By eyeball, I decided that from ten feet at the front, the roof would slant up to 15-feet above the ground at the base of the clerestory wall, and that it should be 22-feet at the top of the clerestory wall and rise from there to 28-feet at the peak toward the rear. I jotted down those numbers and started cutting out parts. Not only did I not make a scale drawing of the structure, but I also didn’t make any pencil marks on the building material. I used to do that: calculate where the ruler should be, pull a pencil along the ruler, and then pull a hobby knife along the pencil line. Then it occurred to me: if the ruler is in the right place, forget the pencil and just pull the knife along it—make the cut and get on with the project!

What Else Ain’t Prototype

While I wanted to make the mill somewhat like the prototype in size and proportions and overall appearance, I also wanted to select components that would be fast and easy to work with. Above all, I wanted to use materials I had on hand. The windows on the model look right to my judgment, but my model has not nearly the number of windows as the prototype. I suppose my model is smaller than the real Centennial and doesn’t have room for all those windows. I placed windows in an arrangement that I thought looked logical.

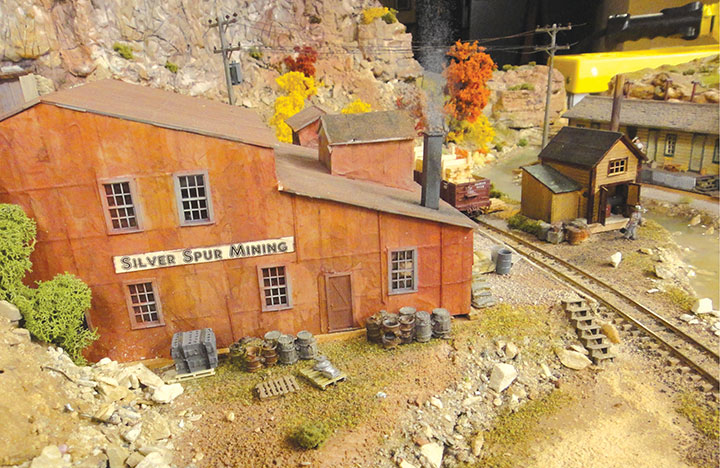

Corrugated metal sheeting is almost universal on Colorado mine structures. I wanted some on my mill and found I had just enough Sylvan plastic material to cover the roof. Another very common siding material for mine structures was tarpaper. After the roof and windows were on, but before the tarpaper siding was applied, I sprayed the all-plastic model with ModelMasters Dark Tan paint from a spray can. That served as the base color of the windows and roof. The paint gave some tooth to the walls so that my paper siding would stick. For tarpaper, I cut scale three-foot-wide strips of tissue wrapping paper. Then I applied Aileen’s Tacky Glue over one wall at a time and spread it evenly with my finger, and then pressed the tissue paper onto it. I let the tarpaper strips run long and then trimmed the excess with a hobby knife. Next, I glued scale 1x2 strips over the tarpaper seams. Finally, the siding was brush painted boxcar red.

Finishing

The final finish on a model is most important in imparting character. The roof was given several brushings of either Doc O’Brien’s or Bragdon powders (I use them interchangeably) in dark rusty red, and brown, and some black colors. I rubbed on more black around the chimney than other areas. This was followed by brush-painting my standard liquid weathering solution which is sometimes Micro-Mark’s gray or my own concoction of rubbing alcohol with a few brushfuls of flat black and a bit of gray swished in it. What proportions? I have no idea; I just experiment until I think it looks right. If you want a worn glazed look on a model, spray on Testor’s Dull Cote while the alcohol is still wet. Neat indescribable effect!

For the tarpaper sides, I dry-brushed Doc O’Brien’s red and some brown, and along the base of the walls some lighter brown and even some yellow. This was all blended and muted by brush-painting the weathering liquid. The windows were given a soaking of the weathering liquid on top of the Dark Tan spray paint. The real wood door was given the liquid weathering stain.

An appropriate interior was constructed as far as could be seen through the open front door and lighted with grain-of-wheat bulbs. The chimney is a Seuth smoke unit. Behind the mill I carved a poor-rock pile out of two-inch insulation foam. The rock pile has a snowshed over the mine track. The shed runs from the mine adit to nearly the end of the pile where supposedly the newest additions to the pile are out in the open. This snowshed is next to the back of the mill so that mine cars can dump directly into the mill. This is a very common Colorado arrangement. There is no evidence that an aerial tramway delivered buckets of ore to the Centennial Mill nor was there a railroad siding behind it; it must have been fed by wagons or trucks that dumped ore into the back of the structure.

And there it is—my Silver Spur mill and mine. It’s not a model of anything specific; it’s a model typical of everything commonplace. That’s what I was after. I hope you’re encouraged to let your imagination wander!